In the first quarter of 2020, the impact of COVID-19 on ceramic foundry sand manufacturer has become an important factor that can not be ignored. Ceramic foundry sand manufacturers have to delay the resumption of work, which brings many challenges to the operation work. The price of ceramic foundry sand has been rising all the way, and even many customers can not get the goods. With the resumption of production of ceramic foundry sand manufacturers, the price level of previous years has been gradually restored.

The main factors affecting the price of ceramic foundry sand are particle size, usage and other factors, with tons as the pricing unit. In addition, bauxite price, electricity price, labor cost, market demand and other factors can also affect the price of ceramic foundry sand.

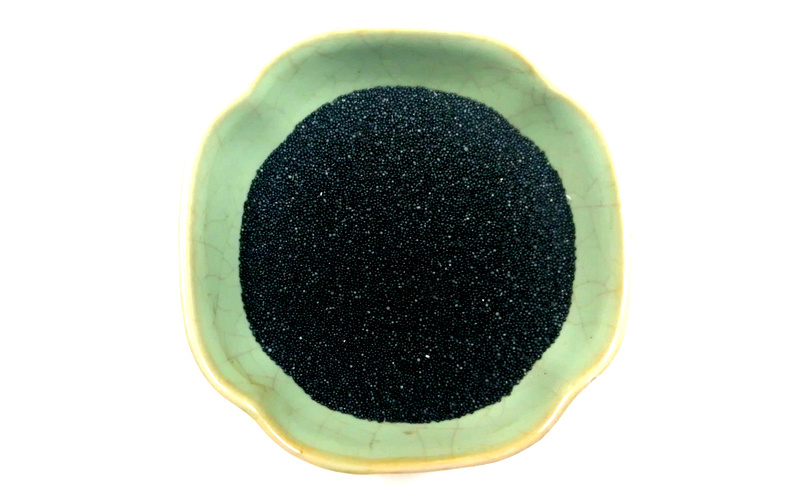

According to its use, ceramic foundry sand can be divided into lost foam sand, resin coated sand, stuffing sand and coating powder. Usually the lost foam casting selects 10-30mesh ceramic foundry sand , also known as coarse sand, with price at around USD400; With the highest price USD600-USD750, the best part of ceramic foundry sand 70-140 mesh is used in precoated sand casting; With the price at about USD480, ceramic foundry sand 20-40mesh is used in stuffing sand casting; Also known as ceramic foundry sand powder, ceramic foundry sand 200 mesh or above is used as coatings with the price at about USD380.

Ceramic foundry sand is used as molding sand in lost foam casting, which makes up for the shortcomings of the previous molding sand in casting and avoids the occurrence of various casting defects. The casting grade ceramic foundry sand has the characteristics of high strength and good durability, and can be recycled. The use of foundry grade ceramic foundry sand can reduce the generation of solid waste and reduce the cost of replacing foundry sand; Ceramic foundry sand is neutral and can be used with most chemical additives. Because of its high fluidity, the success rate of manufacturing thin-walled castings is improved, and the finished product rate of castings is maximized.

Ceramic foundry sand is suitable for resin sand casting, precoated sand casting, refractory coating, lost foam casting, V process casting, shell mold casting and precision casting. It is widely used in aerospace, ships, railway locomotives, wind power, high-end pump valves, machine tools, engines, automotive accessories, mining machinery and other casting molding processes. In addition, it has also been applied to the treatment of ladle flowing sand, soluble mould core and surface shot peening.