The quality of foundry sand directly affects the quality of castings, which will produce defects such as blowhole, pinhole, slag inclusion and burn-in, affect the appearance quality and internal quality of castings, and in serious cases will make castings rejected.Especially in recent years, the rapid development of advanced technology such as resin bonded sand, resin coated sand, ester cured sodium silicate sand and so on, put forward higher requirements for the quality of foundry sand. Foundry sand choice is even more important.

In the foundry industry, ceramic foundry sand has been widely used to produce high precision castings. It is a neutral material, which can be used together with both acid and alkali binders; The excellent working properties make it suitable for the production of various metal castings.

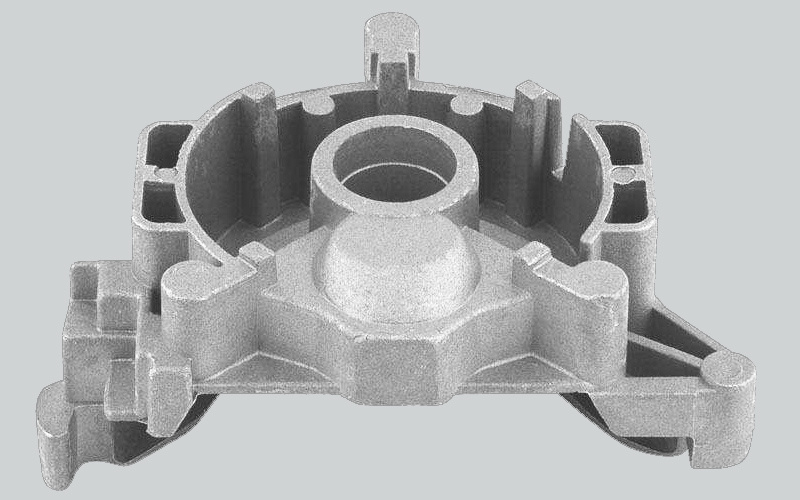

Ceramic foundry is a kind of sand for steel castings and precision castings developed jointly by casting technology experts. It has been proved that it is not only resistant to high temperature, easy to crumble, high surface finish, but also has good usability, and its cost performance is much higher than chrome ore and quartz sand. It is the most important and ideal modeling material for casting carbon, alloy steel (heat-resistant steel, corrosion-resistant steel, high-temperature steel) and so on.

Ceramic foundry sand is a kind of neutral material, which is made of high temperature resistant hot melt peritoneum. It has compact structure, high thermal conductivity, high temperature stability, no cracking, acid resistance, alkali resistance and no change under the use of oxidant and reductant and various metals. The ceramic foundry sand with the above properties can be used for producing castings, which can improve the quality, reduce the casting defect rate and reduce the production cost.The emergence of ceramic foundry sand makes it possible to produce complex castings that could not be produced before, and makes the development of foundry industry a higher level. Many casting defects can be avoided, and the production quality can be improved.

Luoyang Ruiyu developed fused ceramic sand, which overcomes the shortcomings of traditional foundry sand. Ceramic sand has good shape, high refractoriness, and perfect stability under high temperature. It is a great cost-effective alternative for chromite sand and zircon sand and has been recognized by foundry experts home and abroad. Currently, Luoyang Ruiyu can produce 30000 tons of ceramic foundry sand with complete specifications every year.