Advantages and Disadvantages of Sodium Silicate Sand Precision Casting Compared with Cold Set Resin Bonded Sand Casting

Release time: 2020-07-29 10:19:44.000

source:

The main difference between sodium silicate sand precision casting and cold set resin bonded sand casting is that it uses different binders and curing agents, so its production processes are different.

In precision casting of sodium silicate sand, sodium silicate is colorless, odorless and nontoxic. It is safe to wash with water after it touches skin and clothes, but it must be avoided to splash into eyes.There is no irritant or harmful gas released from water glass in the process of mixing sand, molding, hardening and pouring, and there is no black and acid pollution.However, if the process is improper and excessive sodium silicate is added, the collapsibility of sodium silicate sand will not be good.Dust flying during sand removal can also cause pollution.At the same time, it is difficult to regenerate the used sand, and the discharge of the used sand causes alkaline pollution to the environment. If these two problems can be overcome, sodium silicate sand can be basically environment-friendly molding sand of no waste sand emissions.

The fundamental measures to solve these two problems: the addition of sodium silicate is reduced to less than 2%, which can basically shake out sand. When the amount of sodium silicate added is reduced, the residualNa2Oin used sand is also reduced. It is possible to maintain the residual Na2O below 0.25% by using simple dry reclamation method.The reclaimed sand can meet the application requirements of single molding sand for medium and small steel castings.At this time, the used sodium silicate sand can be recycled in full, and the sand-iron ratio can be reduced to less than 1:1, even if it is recycled by the simpler and cheaper dry method instead of the expensive wet method.

The resin bonded sand has many advantages such as high dimensional precision, smooth surface, high molding efficiency, capable of producing castings with complex shape and strict internal quality, easy reclamation and so on. However, the production cost of resin sand is high, and the environmental pollution is serious. Under the increasingly stringent requirements of people's living conditions and environment, the application of resin sand is limited because of the great investment in labor protection and production environmental sanitation. But water glass is colorless and odorless, and there is no gas leakage in the process of mixed sand modeling, hardening and casting. Therefore, in recent years, many countries pay attention to sodium silicate sand again.

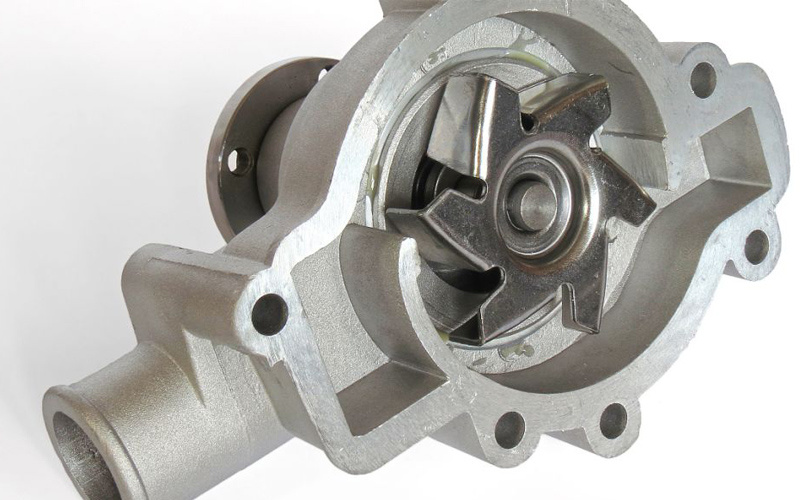

Sodium silicate sand casting: use sodium silicate as binder and quartz sand to make molding sand by mixing them in a certain proportion, blow carbon dioxide to solidify after molding, then draw the mould, assemble the mould and pour into castings.

For cold setting resin sand casting, use resin as binder (need to add hardener) and quartz sand to make molding sand by mixing in a certain proportion, after molding and natural curing at normal temperature, then draw the mould, assemble the mould and pour into castings.

Previous: No

Next: Casting Process Flow

More News

Problems in Casting Process of Lost Foam Casting

Lost foam casting (LFC) process has been developed rapidly in recent years because of its low investment and low cost.The gating system plays a very important role in the lost foam casting process, an

The V process casting originated in Japan. It uses plastic film to vacuum to make dry sand molding, that is, physical modeling.Because it does not use binder, shakeout is simple and convenient, the co

It has become a trend for foundry industry to move from tradition to intelligence

It has become a trend for foundry industry to move from tradition to intelligence.The typical application mode of intelligent casting is digital foundry, which uses information technology to manage al

多行文本内容元素

富文本内容绑定数据后可解析HTML语言内容

LUOYANG RUIYU CERAMIC SAND CO., LTD.

Tel:+86 379 65110927

Fax:+86 379 65110921

Email:lyry@lyruiyu.cn

Website:www.lyruiyu.cn www.foundry-sand.cn

Address: Gaolong Town, Yanshi county, Luoyang, Henan, China

Mobile site

WeChat public account